hörSort GLASS TABLES

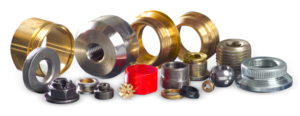

AUTOMATICALLY MEASURE AND SORT TURNED PARTS

hörSort glass tables were developed especially for rotationally symmetrical turned parts.

Your advantages:

- Flexible automation.

- Low-cost 100% control.

- Precise sorting.

- Maximum efficiency.

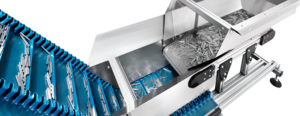

The hörSort system with its glass table is a modular construction, which means all components can be individually adjusted to match your requirements. The central unit is an image processing system that facilitates multifaceted and complex checking and control functions.

The turned parts are precisely placed on a glass table, then measured and sorted. Tests include dimension checking of components as well as surface inspection and thread testing.

Special tasks which cannot be solved in the actual test on the glass table can be implemented via an upstream rotary indexing table with an appropriate special application.

DELIVERY INCLUDES:

- Automated sorter with bunker

- Pre-selector unit

- Part guidance with good/reject switch gate

- Basic frame complete with guard panels

- Cameras with high quality lenses

- Image processing system

- Software

- TFT monitor, keyboard, mouse

- Lighting system

- Documentation in quality ring binder

- Programming examples

- Tutorial